This is the first in a series of posts on metal-working written by Dr. Kevin Leahy, PAS National Finds Adviser. The articles were first published in The Searcher magazine and are reproduced here with kind permission from Harry Bain, editor for The Searcher.

Gold is, perhaps, the strangest of the metals not through its inherent properties (interesting as they are) but through gold’s social role. Here we have a metal grubbed from the earth at great cost and labour, and because of which countless people have died, but which is effectively useless. Tools and weapons were made from stone, bronze and iron but, until recently, when high-tech applications appeared, gold’s only use was decorative and as a high level means of exchange.

Britain is lucky in having its own sources of gold. These are all in the north and west – Ireland, Wales and Scotland. The gold is present in the ancient hard rocks of these areas to which it was brought, from deep with the Earth, by volcanic and hydrothermal activity. However, these rocks have been eroded and so redeposited gold can be extracted from streams by “panning”, swirling sand around in a shallow, water-filled dish so that the sand is washed away, hopefully leaving a smudge of gold dust in the centre.

What is it about gold that gives it its allure? Soft and weak its mechanical properties are hopeless but it does offer the advantage of being very easily worked. It is highly malleable and can be beaten so thin that it becomes transparent. It can also be cold-welded by hammering and offers a craftsman almost unlimited possibilities.

Then there is its colour. Most metals are either grey or white; only gold and copper are coloured. But unlike copper, gold does not tarnish – even after long burial it remains lustrous and bright yellow, the colour of the sun. Gold is also dense and has “heft” – if you toss it in your hand you can feel it landing on your palm. Finally, gold is scarce and scarcity makes it desirable to those with the power to obtain it.

By about 5000BC gold was being used to make trinkets in Eastern Europe. Its early use was due to it occurring in a “native” state, not as an ore that needed to be smelted but as metallic gold which just needed to be beaten to shape and cold-welded to form small objects.

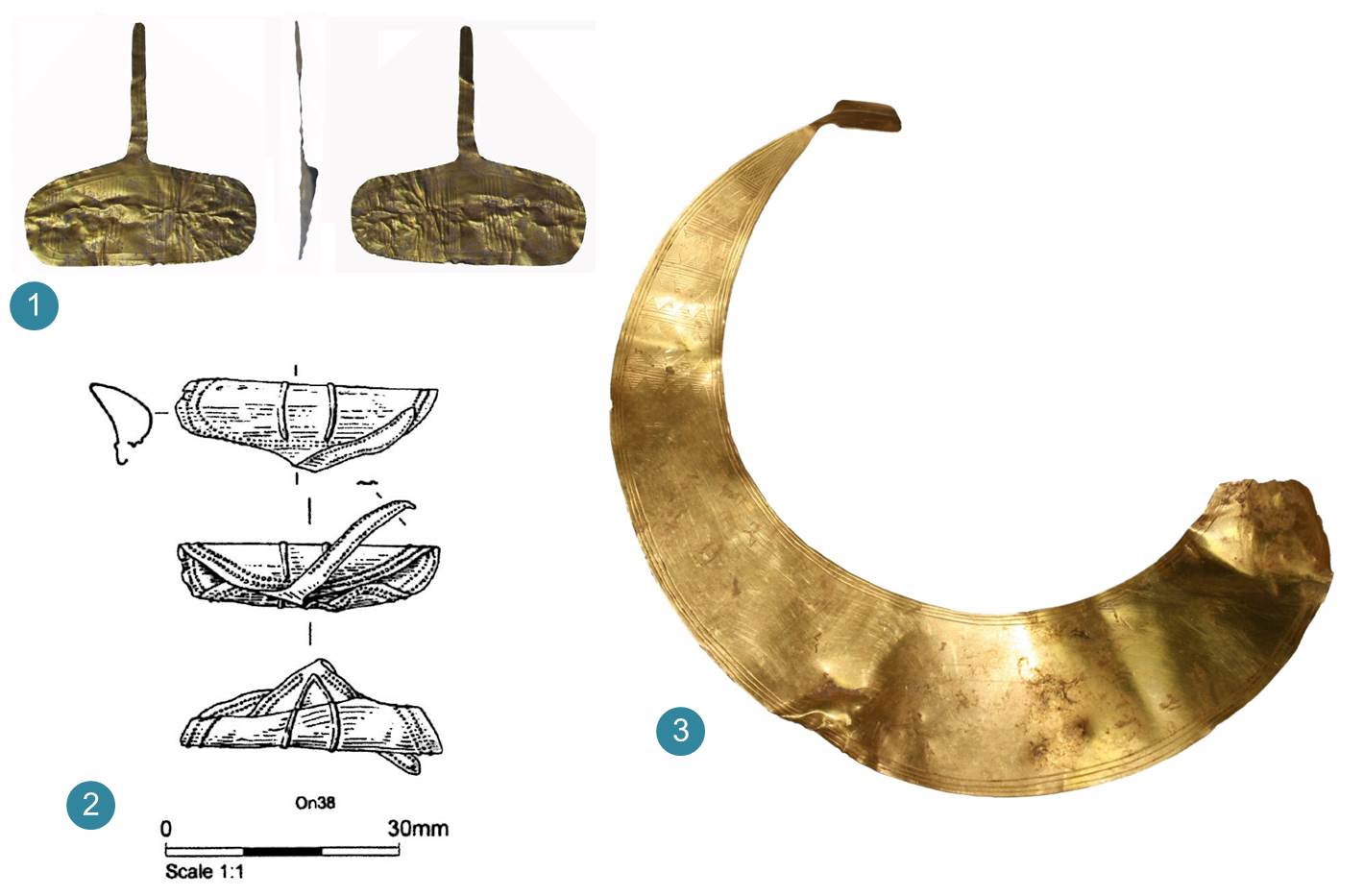

Gold working appears in Britain around the middle of the third millennium BC when “basket ornaments” were placed in Late Neolithic/Early Bronze Age “Beaker” graves; that of the celebrated Amesbury archer was dated to 2470BC. In this period we find small gold discs (about 30mm in diameter) with raised decoration and also gold “lunulae”. Lunulae bear incised, zig-zag linear decoration similar to that seen on beaker pottery suggesting that they are of similar date, although there are no examples from graves or anything else that might date them. We also don’t know who wore them or how they were worn – were they around the neck or inverted on the head? Most lunulae have been found in Ireland where they must have originated but a few stray into Britain and onto the European mainland.

Similar in shape, if not in decoration, to Bronze Age beakers is the wonderful cup found at Ringlemere, Kent, in 2001. Beaten from a sheet of gold, its corrugated sides more than compensate for the lack of an incised pattern.

From later in the Early Bronze Age (up to c.1700BC), we get a series of small amber pendants covered, at least in part, by thin gold sheet; also dagger pommels decorated with hundreds of tiny gold nails. These are found in graves of the so-called Wessex Culture but so far none have been recorded on the Database.

Although important technical advances continued to be made in bronze working, gold seems to disappear with the end of the Wessex graves, or perhaps they were putting it somewhere where we can’t find it. Gold reappears big-time around 1400BC as part of the Middle Bronze Age “Ornament Horizon” which included gold bracelets, neck rings and ornaments often made from twisted bars. These objects aren’t based on earlier British Bronze Age types but are new forms introduced from the Continent. Some hoards of this period were enormous – the Mountfield, Sussex, hoard contained 13lb of gold.

After 1100BC we have another gap in our knowledge of British gold working. Things start to pick up again with the production of gold bracelets. Most of these are found in hoards, usually of around three bracelets, sometimes with bronze objects. These come in a range of simple shapes with round, flat, D-shaped and hollow C-shaped sections. Most had expanded buffer terminals although the flat type had scrolled ends.

Of similar date is the so-called “ring money” consisting of small penannular rings sometimes decorated with bands of different coloured alloys. The function of these rings is unknown but it is unlikely that they were any sort of money. Lock rings represent another enigmatic object. The two faces and inner edge were fixed together with binding strips to form a hollow triangular section. Lock rings are in Britain, Ireland and north-west France but we have no idea of how they were used.

One of the emblems of the Iron Age is the gold torc. These splendid objects are, like so much else in archaeology, mystifying. They don’t stand at the apex of any deep tradition of gold working but represent, with the exception of coins and a few late brooches, the totality of Iron Age gold working. Made using techniques drawn from copper-alloy working these objects stand alone.

Some of the discoveries have been amazing: excavations at Snettisham, Norfolk, revealed at least 12 hoards packed together into pits. Some of these torcs showed signs of wear and others look like continental imports. The alloys from which they were made became increasingly debased with the later torcs contained less than 25% gold. Mercury gilding, in which gold is dissolved in mercury for application to a silver or copper-alloy object appeared for the first time.

The Iron Age saw the large-scale use of coins, many of which were made from gold or “electrum” (a gold/silver alloy). This is not the place to discuss the massive and complex topic of Iron Age coins but one aspect of them is interesting from a technical point of view: we find tray-like slabs of pottery which bear rows of hollows. These may have been used to ensure the alloy composition of the coins was correct. Into each hollow was weighed the correct amount of gold, silver and copper, and the tray was then placed into a furnace so that the scraps of metal fused together to form a pellet of the right weight and composition ready for striking coins.